Scaffolding Great Harwood Lancashire: When you've got some major building work to do on your business or home in Great Harwood, for example having the chimney stack rebuilt, changing your windows, repointing your home's brickwork or re-felting your roof, there's a high probability that you're going to need to have some scaffolding erected, to help make the area safe for both you and the workmen carrying out the project. If this is in fact the case, then you will need to get in touch with a recognized Great Harwood scaffolder, to supply you with some costings and get the required scaffolding set up correctly and safely. This isn't a thing to scrimp on, because it has to be done properly, and you should always use a recognised scaffolder, and avoid cowboys and rogue traders no matter what the cost.

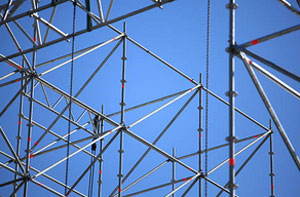

Scaffolding - An Overview: Normally made from steel tubes and fittings, a scaffold is actually a temporary structure that's installed to provide a sturdy platform that is safe for workmen carrying out their duties on homes and structures in Great Harwood. Shielding the public and occupiers from falling objects is also a necessary aim of scaffolding, that makes the surrounding environment less dangerous. A risk assessment is likely to be necessary to confirm if a scaffold is needed for any specific job.

To make a scaffolding platform, you will need a variety of different components including: scaffold boards, toeboards, putlogs, base plates, couplers, sole boards, ladder clamps, swivel clamps, facade braces, ladders, sills, guard rails, spade ends, limpet clamps, diagonal braces, right angle clamps, midrails, ledgers, board clamps and standards.

To confuse things even more, there are cantilever scaffolds, double scaffolding (masons scaffolding), tube and fitting scaffolds, patented scaffolding, rolling scaffolds, confined space scaffolds, tower scaffolds, shoring scaffolds, trestle scaffolding, single scaffolding and suspended scaffolds, each kind covering its own specific objective. The most widespread type and the one which the majority of property owners in Great Harwood will likely need for their improvements or repairs is the single scaffold. However, if you are dealing with a business premises, you might require any of the types mentioned above.

When you need to get scaffolding in Great Harwood, you must search for a proficient scaffolding contractor, who's approved by the local council. If your scaffolding is going to encroach onto the road or public pathway you will need permission from your local council and will need to make sure that it's safe before it's used, thoroughly re-check it every seven days, as well as safety test it after damage, inclement weather or alterations to the scaffold . These local authority licences are needed for several positioning tasks including access towers, scaffolding, hoardings, staging, pedestrian barriers and also builders plant or skips. Any scaffold that is erected on a public highway must have adequate safety lighting fitted. So that it can meet up with the requirements for the design of access and working scaffolds, any scaffolding in the United Kingdom must observe the European Standard, BS EN 12811-1.

You'll likely be aware of a couple of scaffolding companies operating in the region when searching for scaffolders in Great Harwood. Their advertising hoardings on scaffolds throughout the area can be easily noticed. Having knowledge of these local companies gives you a foundation to begin your selection process. Expanding your options is possible by submitting a request through Bark, a web-based services marketplace that streamlines the process by connecting you with local scaffolders and tradespeople. A substantial amount of time and effort can be conserved when utilising this approach. Speedily, you'll amass a substantial group of possible scaffolders, empowering you to make an informed decision for your construction or renovation, thereby ensuring a scaffolding solution that is safe, efficient, and tailored to your needs.

Scaffold Tower Hire Great Harwood - A scaffold tower could be acceptable if your project is a small one, meaning you'll have lots more options. It is possible to hire a tower scaffold from tool hire companies, building merchants and sometimes even certain scaffolding companies might be prepared to provide one on hire. You should try enquiring at Travis and Perkins, HSS, Jewson, Hire Station or other local tool rental firms, should there be any near to you.

To ensure they are simple to transport and to move when in situ, scaffold towers are generally constructed from lightweight aluminium tubing. They are commonly for hire in several styles and sizes. For more or less any type of task you can make a choice from single person towers, cantilever towers, microfold towers, podium steps, guard rail scaffold towers, non-conductive towers, stairwell access towers, single width alloy towers, double width scaffold towers, span access platforms, folding low level platforms, tower bridging decks, folding indoor scaffold towers and other custom scaffolding towers or work assisting towers. If you've got a lot of work to do on your house, you may even consider buying a basic scaffold tower, seeing that they are moderately priced and may work out less costly than repeatedly hiring one.

It's essential to comprehend the various types of scaffolding and components that are available if you're planning to undertake a building project that needs it. The article explains that scaffolding is a complex system of tubes and fittings that are clamped and fastened together, resulting in a secure platform for working at height.

Additional features like staircases, hoists and loading bays can be included in scaffolding systems to facilitate the movement of equipment and building materials to and from the scaffold platform, besides the components outlined in the article.

The local authority must approve and essential safety guidelines must be followed by the scaffolder in Great Harwood, which is crucial when making a choice. This includes frequent safety checks before and during the use of the scaffold, as well as obtaining any necessary permits for scaffolding that encroaches on a public highway or pavement.

Regardless of whether you're a homeowner or a business owner, safety must be given the utmost priority when it comes to scaffolds. The safety and efficiency of your building project can be ensured by choosing a competent and reputable scaffolder in Great Harwood.

The Skill of the Scaffolder: Construction with Safety in Mind

Building a scaffold is a detailed process that requires a distinct set of skills. Below is an outline of the important qualities that are necessary for an adept scaffolder:

Technical Expertise:

- Structural Integrity: Their expertise in load-bearing capacity enables them to distribute weight evenly across the scaffold and detect any potential weaknesses, therefore ensuring the structure's safety in supporting materials, equipment and personnel.

- Reading Blueprints: Scaffolders meticulously translate blueprints into reality. By understanding the specifications and layout, they determine the dimensions, weight restrictions and anchor points necessary for an effective and safe scaffold.

- Knowledge of Components: Scaffolders possess knowledge of all parts of a scaffold system, such as couplers, tubes, base plates, braces and platforms, comprehending their particular roles and the way they interact to form a secure and safe framework.

Physical Abilities:

- A Head for Heights: Working high off the ground is an inherent part of the job. Scaffolders should be comfortable working in elevated positions and have a good sense of spatial awareness.

- Balance and Agility: Erecting scaffolding commonly involves navigating tight spaces and navigating through a complex network of metal, sometimes at considerable height. For safe and secure traversal, scaffolders need to demonstrate remarkable balance and agility.

- Stamina and Strength: Due to the weight of a scaffold's components, scaffolders must have ample strength and stamina for lifting, securing and positioning these parts during the construction phase.

Focus on Safety:

- Safety Awareness: Scaffolders serve as safety watchdogs within building sites, constantly assessing the scaffold for compliance with safety regulations. They hold the critical role of highlighting any potential perils or unsafe work habits to the rest of the team.

- Inspection Procedures: Scaffolders are trained to conduct routine reviews as part of the essential measures for preserving a safe work setting, quickly identifying and resolving issues such as improper connections, damaged parts or loose components to prevent accidents.

- Fall Protection Protocols: Scaffolders undergo extensive instruction in fall protection techniques, which include the proper employment of personal protective equipment (PPE) like safety nets, harnesses and lanyards, making sure that every person working on the scaffold employs fall protection apparatus appropriately.

Communication Skills:

- Problem-Solving Skills: Scaffolding tasks can present unpredicted problems. Scaffolders are required to demonstrate proficient problem-solving skills to seek out solutions and tailor their approach, maintaining adherence to safety standards throughout.

- Clear Communication: Scaffolders collaborate intimately with supervisors, other construction workers and engineers, necessitating clear communication to guarantee a shared understanding of the scaffolding plans, possible risks, and restrictions on load.

Scaffolders, by honing these vital skills, are instrumental in enhancing and safeguarding the effectiveness of building projects. Serving as the industry's foundation, they permit others to confidently rise to new heights.

In places like Altham, Tottleworth, Brockhall Village, Huncoat, Brownhill, Hindle Fold, Clayton-le-Moors, Accrington, Church, Padiham, Altham West, Cliffe, Whalley, Blackburn, Rishton, Oswaldtwistle, Billington, Hapton, in these postcodes: BB6 7EQ, BB6 7AB, BB6 7FD, BB5 5SL, BB6 7HX, BB6 7BA, BB6 7AQ, BB6 7JH, BB6 7NP, and BB6 7JP, and also others near to Great Harwood, these vital scaffolding services are still accessible for those people who require them.

Cuplock Scaffolding

You might be aware that there are several "module" or "system" scaffolding options available, and the first one called Cuplock (or Cuplok®), which some would say is still the best, was introduced by a scaffolding company called SGB. Largely down to its flexibility and simplicity, Cuplock is these days one of the most commonly used scaffolding systems across the globe. Cuplock is fast and easy to use, due to its unique locking system, and it is adaptable for use in a range of scenarios including curved scaffolding, birdcage scaffolds, stairway access scaffolds, shoring scaffolds, loading tower scaffolds, facade scaffolds and mobile scaffold towers. Cuplock scaffolding has grown in popularity, especially over the last thirty years, with building companies in Great Harwood constantly trying to find ways to save money. Employing a "cup and blade" concept, with a twisting action to firmly lock the different standards and ledgers together, Cuplock is a galvanised "module" or "system" type of scaffolding. (Tags: Cuplok® Scaffolds Great Harwood, Cuplock Scaffolds Great Harwood, Module Scaffolding Great Harwood, System Scaffolds Great Harwood)

The Various Styles of Scaffolding

- Patented Scaffolding

- Shoring Scaffolds

- Suspended Scaffolding

- Tower Scaffolds

- Trestle Scaffolds

- Tube and Fitting Scaffolds

- Rolling Scaffolds

- Confined Space Scaffolds

- Cantilever Scaffolding

- Double Scaffolds (Masons Scaffolding)

- Single Scaffolds

Scaffold Fencing and Hoardings Great Harwood

Scaffolding hoardings and fences are two kinds of non-permanent structures that are used in various applications that require a non-permanent barrier or screening. Whether it's an event, a construction site, or any other location in need of protection, these structures provide a fast and easy way to safeguard the area. These structures are generally made from timber, metal or plastic.

Scaffolding fencing is used to encompass scaffolding systems and keep the public and workers safe from the potential dangers of falling debris or unsteady structures. These fences are adjustable, which allows them to be adapted to fit the size and configuration of the scaffold, making them an adaptable solution for the construction sites on which they are used.

Hoardings, on the other hand, are used for the purpose of hiding construction sites, event preparation or public works from being seen. They help to preserve the privacy and appearance of the area and are typically built from materials like corrugated metal, wood sheets or plastic panels. These hoardings are often made into attractive and eye-catching screens by decorating them with graphic designs.

Both scaffolding hoardings and fences play a crucial role in preserving the safety of the general public, workmen, and the environment during events or construction projects. They are durable, quick to install, and can be removed easily once the work is complete.

Scaffold Boards

Now, we have all seen scaffold boards on construction sites in Great Harwood, and lots of Great Harwood householders have got scaffold boards in their gardens and homes. Generally considered to be strong and durable, scaffold boards can prove useful between ladders for decorating, for bridging muddy patches, for raised beds in the garden, and a multitude of other diverse chores. Although, we aren't advocating such usage here!

However, the use for which scaffold boards in Great Harwood are intended is to create a strong working platform for workers on scaffolds. Fitted lengthwise along scaffold lifts, these boards must be supported at intervals that are determined by a number of variables, but especially by the grade and quality of the scaffold boards which are being used.

Scaffold boards in the UK generally come in lengths ranging from 5 feet (1.5m) to 13 feet (3.9m), and are typically 225mm wide and 38mm thick. To prevent the weaker end grain of the boards from splitting, timber scaffold boards are easily identified by the metal band that's fastened to both ends of each board. Scaffold boards aren't necessarily all manufactured from timber, and they are available in various different types and grades.

The Different Types of Scaffold Boards

Grade "A" Scaffold Boards - Scaffolders throughout the UK have for many decades seen grade "A" scaffold boards as the default board type, and used them as standard. The fact is though, that grade "A" scaffold boards aren't up to British Standards requirements, and whilst they rarely break, they should not be the favoured choice for use on-site.

BSI Standard Scaffold Boards - Observing the British Standards (BS 2482:2009), this sort of scaffold board is the recommended grade and quality for use on construction projects in Great Harwood. The metal end band will contain all the particulars for identification including whether they've been visually or machine graded (V or M), and the British Standards mark. To fulfill the recommendations these boards should be supported at 1.2m (3.9 ft) intervals.

Plastic Scaffold Boards - Scaffolding contractors in Great Harwood also choose to use plastic scaffold boards which are more rot and water resistant, are more durable and are non-slip.

Galvanised Metal Scaffold Boards - British Standards (BS EN 12811) compliant steel scaffold boards are easy to clean, strong, durable and flame retardant, they are especially useful in harsh climates.

Flame Retardant Wooden Scaffold Boards - Scaffold boards which are flame retardant up to Class C of BS EN 13501-1 (British Standards), can be purchased in wood when required.

Scaffold Dismantling

Just as putting up scaffolding is important, so is the careful dismantling of it, which requires a fair amount of precision and expertise. After completing a project, safely taking down the scaffolding is key to ensuring the site can be cleared efficiently without risking anyone's safety. It might look like an easy job, but removing scaffolding involves careful planning to avoid accidents, as even a tiny mistake can cause big problems. That's why it's always best to trust this task to trained professionals.

Engaging a professional team means they'll approach the dismantling process methodically, ensuring that each part of the structure is removed in the proper order. Starting from the top, they'll systematically work downwards, taking sections off one at a time to ensure everything stays balanced and stable. This careful approach minimises risks and keeps the vicinity safe for workers, properties, and the public. Furthermore, with the right tools at their disposal and their wealth of experience, these professionals are able to quickly identify and resolve any unexpected challenges that might surface during the dismantling, reducing stress and conserving time.

Hiring specialists for scaffold dismantling goes beyond just safety; it's also about doing the job efficiently. They'll finish the work quickly and to a high standard, allowing your site to get back to its usual state as soon as possible. Whether you're dealing with a home renovation or a large commercial project in Great Harwood, having the right team on board makes a significant difference. A well-executed dismantling process ensures that everything runs seamlessly, giving you one less worry. (Tags: Scaffold Dismantling Great Harwood).

Scaffolding Signage

Scaffolding signage is a critical element that cannot be overlooked in any maintenance or construction project where scaffolding is used. Signs serve to notify workers and the public of the presence of scaffolding and potential risks. The types of scaffolding signage can range from warning signs to information and directional signs, which could provide contact information for the scaffolding company or emergency services.

To comply with relevant health and safety regulations, signs should be legible and conspicuous from a distance. The use of scaffolding signage reduces the risk of injuries and accidents by notifying workers and the public of potential hazards and providing them with vital information. It is therefore important for scaffolding companies in Great Harwood to make sure that appropriate signage is in place before erecting any scaffolding structure. Proper placement and maintenance of scaffolding signs can promote a favourable image of a company, highlighting their commitment to safety and adherence to regulations. In vast and intricate projects, scaffolding signage can act as a wayfinding tool, helping workers and visitors navigate the site, as well as providing safety information.

Scaffolding Weather Protection

For construction safety, scaffolding weather protection is indispensable, allowing workers to operate efficiently and safely, irrespective of the climatic conditions. Temporary structures are built surrounding scaffolding to shield it from the detrimental effects of rain, snow, wind, and other harsh elements.

A number of common scaffolding weather protection systems are:

- Scaffold shrink-wrap: This durable plastic material is heat-sealed to the scaffolding frame, forming a watertight enclosure and protecting the worksite from the elements.

- Encapsulation systems: These systems involve entirely surrounding the scaffolding structure with weatherproof materials, establishing controlled workspaces for sensitive tasks or preventing dust and debris from escaping the work area.

- Temporary roofs: Comprising metal frames and waterproof materials like polycarbonate panels or tarpaulins, these temporary structures provide overhead protection from snow, debris and rain, safeguarding workers and ensuring project continuity in any weather.

Effective scaffolding weather protection offers several benefits:

- Controls debris and dust: Encapsulated scaffolding systems effectively enclose debris and dust, preventing their uncontrolled release into the encircling environment.

- Maintaining material durability: Prevents damage to construction materials from rain, snow and wind, ensuring their durability and reducing project costs.

- Sheltering workers from the elements: Fosters uninterrupted work regardless of weather conditions, preventing delays and safeguarding worker safety.

- Reduces environmental pollution: Ensuring the surrounding environment remains free from construction-related debris and pollutants, scaffolding weather protection systems safeguard local ecosystems.

Investing in proper scaffolding weather protection systems is essential for ensuring the safety of workers, project efficiency, and environmental protection during construction projects.

Scaffold Debris Netting

To contain and prevent debris from falling, scaffold debris netting, a protective mesh material, is installed on scaffolding. Its purpose is to act as a safety measure, safeguarding workers, passers-by, and the surrounding areas from potential hazards. This netting is designed to be durable, lightweight, and easy to install. It serves as an effective barrier, thereby minimising the risk of falling objects and reducing the risk of damage or accidents. In Great Harwood, scaffold debris netting is a crucial factor in maintaining a safe working environment on construction sites. Debris netting is carefully manufactured to meet the unique demands of building sites. This product is engineered to be durable and withstand prolonged exposure, adverse weather conditions and the rigours of construction activities. The netting is a durable and lightweight option that is easy to install and manoeuvre. The efficiency of building projects is increased by the simplicity of its application, which allows for swift installation and removal. (24862 - Scaffold Debris Netting Great Harwood)

To contain and prevent debris from falling, scaffold debris netting, a protective mesh material, is installed on scaffolding. Its purpose is to act as a safety measure, safeguarding workers, passers-by, and the surrounding areas from potential hazards. This netting is designed to be durable, lightweight, and easy to install. It serves as an effective barrier, thereby minimising the risk of falling objects and reducing the risk of damage or accidents. In Great Harwood, scaffold debris netting is a crucial factor in maintaining a safe working environment on construction sites. Debris netting is carefully manufactured to meet the unique demands of building sites. This product is engineered to be durable and withstand prolonged exposure, adverse weather conditions and the rigours of construction activities. The netting is a durable and lightweight option that is easy to install and manoeuvre. The efficiency of building projects is increased by the simplicity of its application, which allows for swift installation and removal. (24862 - Scaffold Debris Netting Great Harwood)

Great Harwood Scaffolding Tasks

Local Great Harwood scaffolders should be able to help you with scaffold shrink wrapping in Great Harwood, patented scaffolds in Great Harwood, suspended scaffolds, construction scaffolding, scaffold designs, supply and erection of scaffolding, confined space scaffolding, bridge scaffolding in Great Harwood, trestle scaffolds, the hire of scaffold boards, shoring scaffolding, Cuplock scaffolding, scaffolding quotes, commercial scaffolding, stairway access towers, scaffold safety fans/nets, scaffolding for sale, highway maintenance services in Great Harwood, passenger and goods hoists, scaffold debris netting, tube & fitting scaffolding, scaffolding permits, hoarding scaffolding in Great Harwood, walkway systems, domestic scaffolds, scaffold tower hire, HAKI roofing systems, hoardings, guardrails and safety, affordable scaffolding and additional scaffolding related services. Listed are just some of the activities that are performed by those installing scaffolding. Great Harwood professionals will be delighted to keep you abreast of their entire range of scaffolding services.

Scaffolding Articles

If have a desire to get some in-depth guidance on scaffolding and scaffolding methods you will find plenty of helpful blog posts and articles on the web. As an example I thought I would include a web link to this awesome article explaining the charter for safe scaffolding.

Scaffolding Enquiries

Latest scaffolding job requests: Kevin and Kelsey Marshall wanted a quote for scaffolding for painting, rendering and brickwork on their semi-detached property near Brockhall Village. Brittany Bradley needed a price quote for 2 scaffolding towers on her detached property in Clayton-le-Moors. Tom and Rachel Wilson wanted a quotation for tin hat scaffolding on their semi-detached home near Oswaldtwistle. Tyler Hill asked for a quote for scaffolding to replace the roof on his terraced property in Hindle Fold. Charles and Heather Morgan wanted a quote for loft conversion scaffolding on their terraced house in Hapton. Jordan and Hannah Foster wanted a quote for scaffolding for painting, rendering and brickwork on their semi-detached property near Oswaldtwistle. Christopher and Maria Scott wanted a quotation for tin hat scaffolding on their semi-detached home near Church. Kayla Harrison needed a price quote for 2 scaffolding towers on her detached property in Whalley. Tiffany Clarke wanted a quotation for scaffolding on two sides of house to remove chimney stack on her detached property in Tottleworth. James and Christina Marsh wanted a quotation for tin hat scaffolding on their semi-detached home near Altham. Laura Phillips wanted a price quote for scaffolding at front of property, for window replacement on her semi-detached house in Tottleworth. Ryan and Sarah Powell wanted a quote for scaffolding for painting, rendering and brickwork on their semi-detached property near Oswaldtwistle. Christopher Kelly wanted a quote for front and rear scaffolding up to eaves on his semi-detached property near Whalley.

Scaffolders Near Great Harwood

Also find: Hapton scaffolders, Blackburn scaffolders, Altham scaffolders, Billington scaffolders, Brockhall Village scaffolders, Rishton scaffolders, Accrington scaffolders, Cliffe scaffolders, Tottleworth scaffolders, Clayton-le-Moors scaffolders, Whalley scaffolders, Hindle Fold scaffolders, Padiham scaffolders, Altham West scaffolders, Brownhill scaffolders, Huncoat scaffolders, Church scaffolders, Oswaldtwistle scaffolders and more. Almost all of these towns and villages are covered by firms who do scaffolding. With their wealth of know-how and expertise, these seasoned professionals guarantee the safe and secure erection of scaffold structures. Understanding the necessity of strict compliance with safety standards and regulations, they create a workspace that boosting productiveness while still minimising the risk of accidents. To get scaffolding estimates, local homeowners can click here.

Great Harwood Scaffolding Services

- Commercial Scaffolding

- Shoring Scaffolds

- Tube and Fitting Scaffolds

- Cantilever Scaffolding

- Mobile Scaffolds

- Scaffolding Erectors

- Scaffolding Hire

- Suspended Scaffolds

- Scaffolding Companies

- Painting Platform Hire

- Scaffolding Solutions

- Domestic Scaffolds

- Industrial Screening

- Construction Scaffolding

More Great Harwood Tradesmen: When on the lookout for Great Harwood scaffolders, you might also be looking out for SKIP HIRE in Great Harwood, loft conversions in Great Harwood, roofing companies in Great Harwood, cladding replacement in Great Harwood, pebble dashing in Great Harwood, rubbish removal in Great Harwood, brick cleaning in Great Harwood, chimney repairs in Great Harwood, repointing specialists in Great Harwood, driveway cleaning in Great Harwood, bricklayers in Great Harwood, window installaton in Great Harwood, painters and decorators in Great Harwood, and other tradesmen.

Scaffolding Great Harwood

Scaffolding Great Harwood Scaffolders Near Great Harwood

Scaffolders Near Great Harwood Scaffolder Great Harwood

Scaffolder Great HarwoodFor the best local Great Harwood info take a look here

Scaffolding Jobs Great Harwood: Find scaffolding jobs near Great Harwood by going here: Great Harwood Scaffolding Jobs

More: Scaffolding Contractors, Scaffolding Specialists, Commercial Scaffolding, Scaffolding Solutions, Scaffolding, Scaffold Specialists, Scaffolding Hire, Scaffolding Firms, Scaffolding Specialists, Cheap Scaffolders, Scaffolding Contractors, Scaffold Companies, Scaffolds and Shoring, Scaffolders, Construction Scaffolds, Scaffolding Solutions, Scaffolding Solutions, Scaffolding Contractors, Residential Scaffolders, Scaffolds, Scaffolds, Residential Scaffolders, Scaffold Companies, Construction Scaffolding, Scaffold Hire, Scaffolding Contractors, Scaffolding for Rent, Construction Scaffolds, Scaffolding Hire, Scaffold Specialists.

Scaffolders in BB6 area, telephone code 01254.

TOP - Scaffolding Great Harwood

Scaffolding Estimates Great Harwood - Temporary Scaffolds Great Harwood - Contract Scaffolders Great Harwood - Scaffolding Wrapping Great Harwood - Scaffolding Services Great Harwood - Scaffolders Great Harwood - Scaffold Hire Great Harwood - Commercial Scaffolders Great Harwood - Scaffolding Great Harwood