Scaffolding Street Somerset: For those homeowners in Street beginning a construction or renovation endeavour, encountering the need for scaffolding is often an essential part of the process. More than just a professional tool, scaffolding is an essential safety provision, enabling work to be executed both safely and efficiently at height. Scaffolding offers a stable platform, enabling workers to effortlessly perform tasks from roof repairs to painting the exterior of a house. From a property owner's perspective, we are set to investigate the domain of scaffolding and scaffolders, spotlighting its importance, the selection methodology, and the principal considerations.

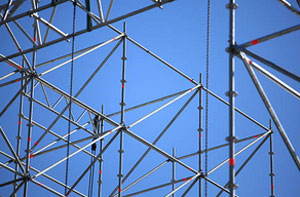

A Brief Guide to Scaffolding: Mainly crafted from steel fittings and tubes, a scaffold functions as an important temporary structure, providing a durable and secure platform for construction workers undertaking tasks on structures and properties in Street. Offering stability and support at various different heights, this framework is meticulously erected to ensure the efficiency and safety of maintenance and construction endeavours. However, its significance surpasses the protection of building workers alone. As a protective barrier, the scaffolding shields not only the labour force but also the general public and individuals living or working within the property premises from risks like falling debris, dust, and potential hazards. Before commencing any construction activity, conducting a comprehensive risk assessment is imperative to ascertain the requirement for a scaffold. Minimising risks and fostering a secure working environment for all stakeholders involved is ensured by this proactive approach, which ensures appropriate safety protocols are followed.

A scaffold is made using several different fittings that will likely include: guard rails, limpet clamps, midrails, putlogs, couplers, sills, diagonal braces, ladder clamps, right angle clamps, board clamps, scaffold boards, swivel clamps, spade ends, toeboards, facade braces, standards, base plates, ladders, sole boards and ledgers.

Subject to exactly what purpose you need a scaffold for, you'll find that there are various different sorts of scaffolding including shoring scaffolds, trestle scaffolding, patented scaffolding, double scaffolding (masons scaffolding), rolling scaffolds, cantilever scaffolds, confined space scaffolds, tower scaffolds, suspended scaffolds, tube and fitting scaffolding and single scaffolds. The most widespread type and the one that the majority of property owners in Street will be likely to need for their home improvements or repairs is the bricklayer's or single scaffold. Nevertheless, if you are working on a commercial premises, you may need any one of the types mentioned above.

For your home improvement projects in Street, prioritise safety above all when using scaffolding. Opt for a respected scaffolding company that holds certification from the local council. For a scaffold that will overhang a footpath or public road, a permit from the council is needed. Vital safety checks must be conducted routinely - prior to initial use, every week thereafter, and after any changes or adverse weather. This applies to scaffolds, and also to staging, hoarding, waste skips, access towers and pedestrian barriers. Remember that any scaffolding that's erected on a public highway must be kitted out with safety lighting. All scaffolding in Great Britain must adhere to the European Standard BS EN 12811-1, which sets stringent design and performance specifications for working and access scaffolds.

When you seek scaffolders in Street, you might become aware of a couple of well known scaffolding companies operating in the region. Those conspicuous advertising hoardings on scaffolds throughout the area, they can be quite difficult to overlook. Familiarity with such local contractors provides you with a starting point for your selection process. To increase your choices, think about sending a request through Bark, a web-based services portal that connects you with local scaffolders while streamlining the process. The adoption of this approach leads to noteworthy time and effort savings Before long, you'll gather a substantial pool of potential scaffolders to enable a well-informed decision for your construction project, ensuring a tailored, efficient, and safe scaffolding solution.

A scaffolder's job is demanding on the body and necessitates a significant amount of technical expertise. Scaffolders are required to comprehend the nuances of various scaffold types, including birdcage scaffolds, suspended scaffolds, and independent scaffolds, each with unique specifications. To guarantee the scaffold's stability, scaffolders need to work out weight loads and employ suitable bracing and ties. Improperly installed scaffolding can lead to collapses or accidents, endangering workers. Therefore, understanding these technical details is crucial.

Scaffold Tower Hire Street - A tower scaffold may be adequate if your building project is only a small one, meaning you will have lots more options. You are able to hire a scaffold tower from tool hire companies, builders merchants and in some cases certain scaffolding companies will be prepared to provide one on hire. HSS, Travis and Perkins, Hire Station, Jewson and similar tool rental providers close to you should be good locations to start your hunt for an appropriate scaffold tower.

Because they have to be simple to wheel around in situ and also easily transported, lightweight alloy is typically used to manufacture scaffold towers. They are generally available in several sizes and designs. Some of the more readily available forms are folding low level platforms, cantilever towers, tower bridging decks, single width scaffold towers, non-conductive (fibreglass) towers, microfold towers, folding indoor scaffold towers, double width alloy towers, span access platforms, 1-man towers, guard rail scaffold towers, stairwell access towers, podium steps and additional custom towers. Buying a basic scaffold tower might even turn out cheaper for you, if you've got a lot of work scheduled on your property. They're reasonably priced and painless to assemble.

It's essential to comprehend the various types of scaffolding and components that are available if you're planning to undertake a building project that requires it. Clamping and tightening together a complex system of fittings and tubes, as discussed in the article on scaffolding, creates a secure platform for working at height.

Besides the components mentioned in the article, scaffolding systems can also contain more features such as loading bays, stairwells and hoists to make the transportation of materials and equipment to and from the scaffold platform more convenient.

When choosing a scaffolding company in Street, ensuring their approval by the local council and adherence to required safety regulations is of the utmost importance. Part of the process involves obtaining necessary permits for scaffolding that encroaches on a public highway or pavement, in addition to carrying out routine safety checks before and during its use.

It's important for both business and home owners to give high priority to safety when it comes to scaffolding. With a reputable and experienced scaffolder in Street, your construction project can be completed efficiently and safely.

The Skill of the Scaffolder:

Scaffolding erection is a meticulous process that calls for a unique set of skills. The following is an overview of the key qualities that make a great scaffolder:

Physical Abilities:

- Head for Heights: Working in high-up places is part of the territory for scaffolders. They should be unfazed by heights and have a solid sense of spatial perception.

- Balance and Agility: Scaffolders often find themselves working in tight spaces and making their way across a tangled network of metal, at times a long way above ground. To do this safely and with assurance, good balance and agility are essential skills for those working on scaffolds.

- Strength and Stamina: Scaffolding system components may be weighty, necessitating scaffolders to have considerable strength and stamina to secure, position and lift these parts during the assembly process.

Technical Expertise:

- Structural Integrity: With their substantial knowledge of load-bearing capacities, they adeptly calculate the weight distribution on the scaffold and recognise any possible weak spots, affirming the scaffold's strength to safely support the load of materials, equipment and personnel.

- Component Knowledge: Knowledgeable about the components that go into making up a scaffolding system - base plates, tubes, platforms, braces and couplers - scaffolders recognise how these elements function individually and in combination to produce a stable support.

- Reading Blueprints: Scaffolders meticulously translate blueprints into reality. By understanding the specifications and layout, they determine the anchor points, dimensions and weight restrictions needed for an effective and safe scaffold.

Communication Skills:

- Clear Communication: Scaffolders maintain a close working relationship with other workers on the construction site, as well as supervisors and engineers, emphasising the importance of clear communication to ensure understanding of the scaffolding plans, weight constraints, potential threats.

- Effective Problem-Solving: Scaffolders can face unexpected challenges during scaffolding projects. They require strong problem-solving skills to find solutions and modify their techniques, all the while upholding safety regulations.

Safety Focus:

- Safety Awareness: As safety custodians on the building site, scaffolders continuously oversee the scaffold's condition, making certain it complies with safety standards. They bear the duty to notify of any hazardous work practices or potential risks to others.

- Inspection Procedures: Routine inspections are a vital part of maintaining a safe work environment. Scaffolders are trained to identify potential hazards like loose components, faulty joints or damaged parts. They address these issues promptly to prevent accidents.

- Fall Protection Protocols: Fall protection protocols, including the skilled use of personal protective equipment (PPE) like harnesses, lanyards and safety nets, form a substantial part of the scaffolders' training, ensuring proper use of fall protection tools by everyone involved in scaffold work.

By excelling in these essential skills, scaffolders are crucial in maintaining the efficiency and safety of construction projects. They're the backbone of the industry, allowing others to attain new heights with confidence.

Compton Dundon, Stone Hill, Butleigh Wootton, Meare, Northover, West Pennard, Walton, Ashcott, Glastonbury, Overleigh, Lower Leigh, High Ham, Baltonsborough, Butleigh, Shapwick, Beckery and more nearby places including these postcodes: BA16 0GY, BA16 0AA, BA16 0EZ, BA16 0GE, BA16 0BQ, BA16 0LY, BA16 0NH, BA16 0ED, BA16 0LZ, and BA16 0DS, are within the range of most Street scaffolding companies.

Birdcage Scaffolds Street

In construction projects, birdcage scaffolds are used as a temporary framework to create a safe and secure working platform. These structures are named for their similarity to birdcages, featuring a complex network of vertical and horizontal bars that form an enclosed framework These scaffolds offer a stable and spacious platform, making them particularly useful for ceiling work or work on other elevated areas indoors.

Building a birdcage scaffold involves the assembly of various vertical poles, which are then connected by horizontal braces to create a grid-like framework. This design ensures stability and can support the combined weight of personnel and materials. Adjustable in size and height to fit diverse spaces, the scaffold is an adaptable choice for a range of construction tasks, including plumbing, electrical work, plastering and painting.

Birdcage scaffolds offer a key advantage in terms of safety. The chance of collapse is reduced by the sturdy foundation formed by the interconnected braces and poles. Improving efficiency and reducing the potential for accidents, workers in Street can move around the platform safely and freely. Birdcage scaffolds are an essential tool in the world of construction, offering an adaptable and reliable solution for working at height. (Tags: Access Birdcage Scaffolds Street, Birdcage Scaffolds Street, Bird Cage Scaffolding Street)

Scaffold Boards Street

Easily obtainable from builders merchants, scaffold boards are frequently seen on building sites and construction projects in Street. Not only that, you'll sometimes also notice scaffold boards being employed for various functions in the homes and gardens of Street, Somerset. Typically regarded as strong and durable, scaffold boards can be useful for bridging muddy patches, across ladders for decorating, for raised beds in the garden, and innumerable other assorted chores. That said, many of these uses can be dangerous, and we are most certainly not endorsing any of those uses here!

However, the use for which scaffold boards in Street are intended is to create a sturdy platform for workers on scaffolding. Scaffold boards are typically mounted horizontally along scaffold lifts, and supported at evenly spaced intervals which will depend on the grade and quality of the boards.

Scaffold boards in Great Britain are commonly 38mm thick, 225mm wide, and are available in lengths ranging from 5 feet (1.5m) to 13 feet (3.9m). To stop any splitting of the weaker end grain of the boards, timber scaffold boards are easy to recognise by the galvanised metal band that is fastened to the ends of each board. Scaffold boards are available in a variety of grades and types, and can be constructed from materials other than just wood.

The Different Grades & Types of Scaffold Boards

Grade "A" Scaffold Boards - Used for many decades by scaffolders across the British Isles, grade "A" scaffold boards have widely been regarded as the default board for those in the scaffolding sector. The fact of the matter is, that grade "A" scaffold boards do not satisfy British Standards requirements, and even though they seldom break and cause problems, they shouldn't be the favoured choice for use on a construction project.

BSI Standard Scaffold Boards - The recommended grade and quality for use on building projects in Street, this kind of scaffold board abides by all of the applicable British Standards (BS 2482:2009). They're either machine or visually graded and the details should be marked on the metal end band. It's recommended that this type of board should be supported at 1.2m intervals in order to be completely safe.

Flame Retardant Timber Scaffold Boards - Scaffold boards which are fire retardant up to Class C of BS EN 13501-1 (British Standards), are available in timber where required.

Steel Scaffold Boards - Compliant with British Standards requirements (BS EN 12811), metal scaffold boards are fire retardant and are incredibly durable and strong.

Plastic Scaffold Boards - Street scaffolding contractors who would rather have boards which are more rot and water resistant, have a longer service life and are non-slip, can choose plastic scaffold boards.

Temporary Roofing Scaffolds Street

Vital for ensuring safe and secure access, temporary roof scaffolds are crucial during both construction and repair work on rooftops. Creating a stable platform with planks and metal poles, these structures enable workers to perform their tasks safely and without any risk of falling. Especially useful for high or steep roofs in Street, they provide a safe and practical alternative to ladders.

Aside from the safety angle, temporary scaffolding helps to protect both the workforce and the property from the weather whilst any construction work is going on. By being covered in reinforced, laminated PVC sheeting, these scaffolds ensure weather protection and waterproofing, enabling work to proceed regardless of bad weather.

Installing temporary roof scaffolding involves putting up a framework around the building, ensuring it is strong enough to support the combined weight of workers and materials. The scaffolding allows for flexibility by being adjustable to different heights and angles, depending on the requirements of the job. To prevent the chance of accidents, it is common to add safety precautions like toe boards and guardrails.

Temporary roof scaffolds benefit not only large construction projects but also smaller repairs and maintenance tasks. Available for short-term hire, they provide an affordable solution for home and small business owners in Street. Ensuring that roofing work is carried out efficiently and safely, these temporary scaffolds provide a secure and dry working platform. (Temporary Roofing Scaffolds Street)

Scaffold Dismantling

Taking down scaffolding is just as crucial as erecting it, and it really does require a lot of care, precision, and expertise. When a project wraps up, it's vital to remove the scaffolding safely so the site can be cleared without putting anyone at risk. Although it may appear simple, dismantling scaffolding necessitates careful planning to avoid any accidents, as even minor errors can lead to significant issues. That's why it's always wise to let trained professionals handle it.

A professional team approaches the dismantling task with a methodical mindset, ensuring every piece of the structure is removed in the right order. They'll start at the top and work their way down, carefully dismantling each section to maintain both balance and stability during the process. This technique helps to minimise risks and keeps the surrounding area secure for workers, properties, and the public alike. Furthermore, with the right tools in hand and their experience, these experts are quick to notice and address any unexpected issues that may come up while taking everything apart, which saves both time and hassle in the long run.

Hiring professionals for scaffold dismantling ensures not just safety but also efficiency. They'll handle the job quickly and to a high standard, so your site can be back to normal in no time. Whether it's a small home improvement job or a large-scale commercial project in Street, the right team makes a world of difference. With a well-planned dismantling process, everything runs smoothly, leaving you with fewer worries. (Tags: Scaffold Dismantling Street).

Safety Tips for Scaffolds

By following one or two simple safety tips, you can easily avoid falls from scaffolding in Street. It does not really matter whether you are using a stationary scaffold or a mobile scaffold, there's always the possibility of an accident happening. Regardless of the style of scaffolding that you're using, adherence to safety guidelines is essential, because serious injuries generally result due to falls from high places.

The first step, and probably the most crucial one, is to make sure there's a capable specialist on the site to take care of the scaffold. All the scaffold construction must be overseen in person by this supervisor. Assistance in scaffold construction and other services will be provided by any scaffolding suppliers in Street worth their salt. Nevertheless, there should be an experienced overseer who should always be present to deal with any scaffold related problem. It's very important to follow the manufacturer's instructions precisely whenever building a scaffold in Street. The manufacturers are always at the end of the line, so if you have any doubts - call them. Remember, there's nothing wrong in seeking help.

Whether it's a stationary scaffold or a mobile scaffold, it is important to ensure that no one works on the scaffolding when there is windy weather about. Accidents involving falls from heights in Street, normally occur during blustery weather. During such adverse weather, it's the responsibility of the safety supervisor to ensure that scaffolds are a "no-go" area. Scaffolding must be checked if it is unsteady or leaning to one side, before any workman climbs on to it. It should be made mandatory for everybody to check this before using any of the scaffolding. This should dramatically decrease the amount of workplace accidents that occur.

Trying to support a scaffold with concrete blocks or loose bricks, is an error that should not be made under any circumstances. It's in your best interests to follow this advice, if the manufacturer says that a foundation is necessary for scaffolding, particularly if it is going to be constructed on a hard surface.

Make sure that you wedge or chock the wheels when you're using a mobile scaffold. This will prevent your mobile scaffolding from rolling. Don't forget, aluminium scaffolding is incredibly light in weight and the chances of the scaffold rolling are always present. Ensuring that you lock the wheels is therefore a really important step.

Finally, it is an absolute no-no to attempt to move a mobile scaffold while anyone is working on it. This blunder is the most common cause of fall accidents from scaffolds.

Scaffolding Weather Protection

Scaffolding weather protection, a cornerstone of construction safety, ensures worker efficiency and safety in all weather scenarios. Erection of temporary structures around scaffolding serves to protect it from snow, wind, rain, and other harsh elements.

A number of common weather protection systems for scaffolding are:

- Temporary roofs: Crafted from metal frames and robust waterproof materials like polycarbonate panels or tarpaulins, these temporary structures provide overhead protection from debris, rain and snow, ensuring worker safety and project continuity in any weather.

- Scaffold shrink-wrap: This robust plastic sheeting is heat-shrunk around the scaffolding frames, providing a watertight seal and protecting the work area from the elements.

- Encapsulation systems: These systems involve completely surrounding the scaffolding structure with weatherproof materials, establishing a controlled environment for sensitive work or preventing dust and debris from escaping.

The implementation of effective scaffolding weather protection unlocks a wealth of benefits.

- Guarding workers against harsh conditions: Facilitates uninterrupted work despite inclement weather, minimising delays and upholding the safety of workers.

- Controls debris and dust: Encapsulated scaffolding systems effectively confine debris and dust within the work area, preventing them from dispersing into the encircling environment.

- Protects the environment: Containing dust, debris, and runoff within the work area, weather protection systems minimise the spread of pollutants, promoting a cleaner environment.

- Shielding material integrity: Shielding construction materials from the elements, prevents damage from rain, wind and snow, ensuring their long-lasting quality and reducing project costs.

Investing in proper scaffolding weather protection systems is a fundamental requirement for safeguarding worker well-being, enhancing project productivity, and promoting environmental sustainability throughout construction projects.

Scaffold Debris Netting

A mesh material called scaffold debris netting is installed on scaffolding to effectively contain and prevent the falling of debris. It plays a crucial role as a safety precaution, safeguarding workers, passers-by, and the surrounding areas from potential hazards. Designed for lightweightness, durability, and ease of installation, the netting offers optimal functionality. It functions as an effective barrier, effectively appreciably minimising the risk of falling objects and lessening the potential for damage or accidents. In Street, scaffold debris netting is an integral part of creating a secure working environment on construction sites. The design of debris netting is carefully tailored to the unique demands of building sites. It is hard-wearing, engineered to withstand prolonged exposure, the rigours of construction activities and adverse weather conditions. The netting is a durable and lightweight option that is easy to install and manoeuvre. The efficiency of construction projects is increased by the simplicity of its application, which allows for quick installation and removal. (24862 - Scaffold Debris Netting Street)

A mesh material called scaffold debris netting is installed on scaffolding to effectively contain and prevent the falling of debris. It plays a crucial role as a safety precaution, safeguarding workers, passers-by, and the surrounding areas from potential hazards. Designed for lightweightness, durability, and ease of installation, the netting offers optimal functionality. It functions as an effective barrier, effectively appreciably minimising the risk of falling objects and lessening the potential for damage or accidents. In Street, scaffold debris netting is an integral part of creating a secure working environment on construction sites. The design of debris netting is carefully tailored to the unique demands of building sites. It is hard-wearing, engineered to withstand prolonged exposure, the rigours of construction activities and adverse weather conditions. The netting is a durable and lightweight option that is easy to install and manoeuvre. The efficiency of construction projects is increased by the simplicity of its application, which allows for quick installation and removal. (24862 - Scaffold Debris Netting Street)

Street Scaffolding Tasks

Street scaffolders should be ready to help with hoardings, scaffolding wrapping, system scaffolds in Street, passenger and goods hoists, industrial scaffolds, shoring scaffolding, hoarding scaffolding in Street, construction scaffolds, scaffolding companies in Street, double scaffolds, scaffold dismantling, shrink wrapping in Street, confined space scaffolding, the hire of scaffold boards, painting platform hire, aluminium stagings, roof scaffolding in Street, walkway systems in Street, walkway scaffolding, temporary scaffold roofs in Street, tower scaffolding, scaffold towers, scaffolding solutions, tower bridge decks, bricklayer's scaffolds in Street, decorating scaffolds in Street, HAKI scaffolding, industrial scaffolding in Street, access scaffolding, rolling scaffolds and other scaffolding related services. Listed are just an example of the tasks that are carried out by people specialising in scaffolding. Street specialists will inform you of their full range of services.

Scaffolding Enquiries

The latest scaffolding projects: Christina Dixon needed a price quote for scaffolding at front of property, for window replacement on her terraced house near Northover. Madison Anderson needed a quote for scaffolding on two sides of house to remove chimney stack on her property in Meare. Timothy Powell from Northover needed an internal scaffold to enable safe working on a commercial building. Taylor Lawson needed a price quote for two scaffolding towers on her detached house near Glastonbury. Ashley Rees needed a quote for scaffolding on two sides of house to remove chimney stack on her property in Baltonsborough. Emily Foster asked for a quotation for hiring scaffolding for her semi-detached house in Shapwick. Daniel Wright wanted a price quote for a covered scaffolding for mending the roof on his terraced property near Overleigh. Ryan and Laura Hall needed a quote for loft conversion scaffolding on their terraced house in Meare. Cameron Price from Stone Hill needed an internal scaffold to enable safe working on a commercial building. Charles Cole needed a quote for front and rear scaffolding up to eaves on his home near Ashcott. Benjamin Lawrence from Compton Dundon needed an internal scaffold to enable safe working on a commercial building. Laura Clarke needed a price quote for two scaffolding towers on her detached house near Lower Leigh. Jasmine Lawrence in Walton asked us "are there any decent scaffolders near me?".

Scaffolders Near Street

Also find: Shapwick scaffolders, Lower Leigh scaffolders, Butleigh Wootton scaffolders, Ashcott scaffolders, Compton Dundon scaffolders, High Ham scaffolders, Beckery scaffolders, Stone Hill scaffolders, West Pennard scaffolders, Northover scaffolders, Overleigh scaffolders, Meare scaffolders, Butleigh scaffolders, Walton scaffolders, Baltonsborough scaffolders, Glastonbury scaffolders and more. Firms who do scaffolding can be found in almost all of these areas. With a wealth of expertise and knowledge, these seasoned professionals ensure scaffold structures are not only correctly erected but also safe. They understand the need for complying with strict regulations and safety standards to establish a work environment that reduces risks and enhances productiveness. Local householders can get scaffolding quotes by going here.

Street Scaffolding Services

- Scaffolding Specialists

- Shoring Scaffolding

- Scaffold Tower Hire

- Tube and Fitting Scaffolds

- Painting Platform Hire

- Scaffolding Solutions

- Mobile Scaffolds

- Cantilever Scaffolding

- Industrial Screening

- Construction Scaffolding

- Domestic Scaffolding

- Scaffolding Erection

- Industrial Scaffolds

- Suspended Scaffolds

More Street Tradesmen: When you are on the lookout for Street scaffolders, you may also be interested in roofing companies in Street, screeding in Street, brick cleaning in Street, rubbish removal in Street, bricklayers in Street, loft conversion in Street, cladding installation in Street, chimney repairs in Street, solar panel installation in Street, gutter replacement in Street, SKIP HIRE in Street, double glazing installaton in Street, brick repointing specialists in Street, and other tradesmen.

Scaffolding Street

Scaffolding Street Scaffolders Near Street

Scaffolders Near Street Scaffolder Street

Scaffolder StreetScaffolding Jobs Street: See scaffolding jobs near Street by going here: Scaffolding Jobs Street

For the best local Street information check here

More: Scaffolding Specialists, Scaffolding Services, Commercial Scaffolding, Scaffolding Suppliers, Domestic Scaffolding, Cheap Scaffolders, Scaffolding Services, Residential Scaffolders, Commercial Scaffolding, Scaffolding Specialists, Construction Scaffolding, Shoring Scaffolds, Construction Scaffolds, Scaffolding, Scaffolds, Scaffolding Services, Scaffold Companies, Scaffolds and Shoring, Scaffolding Services, Shoring Scaffolds, Scaffolding Firms, Scaffolding Services, Scaffolding Services, Scaffolding Solutions, Scaffolding Firms, Scaffolds, Residential Scaffolding, Scaffolding Hire, Scaffolding Suppliers, Construction Scaffolds.

Scaffolders in BA16 area, (dialling code 01458).

Scaffolding Near Me - Scaffolding Wrapping Street - Scaffolding Erectors Street - Temporary Scaffolds Street - Scaffolding Street - Commercial Scaffolding Street - Scaffolding Hire Street - Domestic Scaffolding Street - Scaffolders Street